Sil-Poxy™ is a one component adhesive made specifically for bonding Smooth-On RTV moldmaking silicone rubbers to silicone rubber and other substrates including some plastics (urethane), plasters/ceramics, fabrics, etc.

Sil-Poxy™ will work with Smooth-On tin or platinum cure moldmaking silicones and provides a strong, flexible bond between silicone parts with high elongation. Can be colored with Silc-Pig™ silicone pigments. Cured adhesive resists weathering, moisture, UV and high temperatures. Sil-Poxy™ can be used repairing torn silicone rubber molds. Other applications include bonding silicone for prosthetics and animatronics.

Cured Sil-Poxy™ is certified skin safe. IMPORTANT - Do not apply to skin in liquid form.

Features

- Can be used repairing torn silicone rubber molds.

- Will work with tin- or platinum-cure silicones

- Provides a strong, flexible bond

Instructions

Safety - Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

Store and use material at room temperature (73°F/23°C). This product has a limited shelf life and should be used as soon as possible.

A clean, dry surface is essential for successful adhesive bonding. If possible, abrade surface and follow with solvent wipe before applying.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

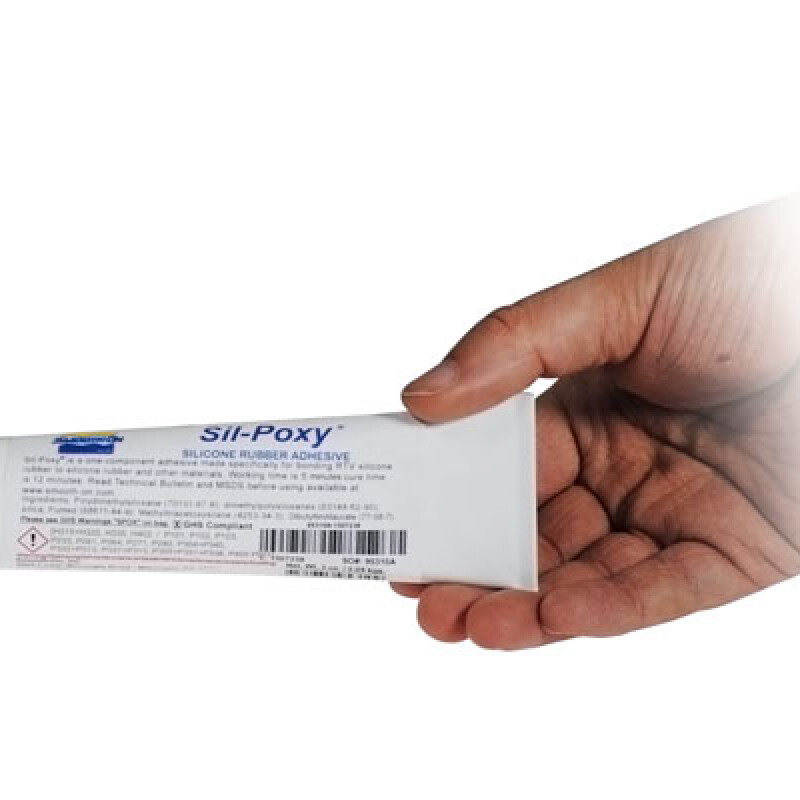

Dispensing - Squeeze tube, taking care not allow air to enter tube before replacing cap. Unused product in tube exposed to air will cure quickly. Replace cap immediately after dispensing.

Applying - Apply adhesive to surface and mate parts. Material will begin to cure in about 5 minutes. Pieces can be handled after 1 hour depending on temperature and humidity. Full cure is attained after 24 hours.

Clean Up - Uncured Sil-Poxy™ can be removed from surfaces using isopropyl alcohol. Do not allow isopropyl alcohol to pool on silicone rubber surfaces.